The Case for LightRay

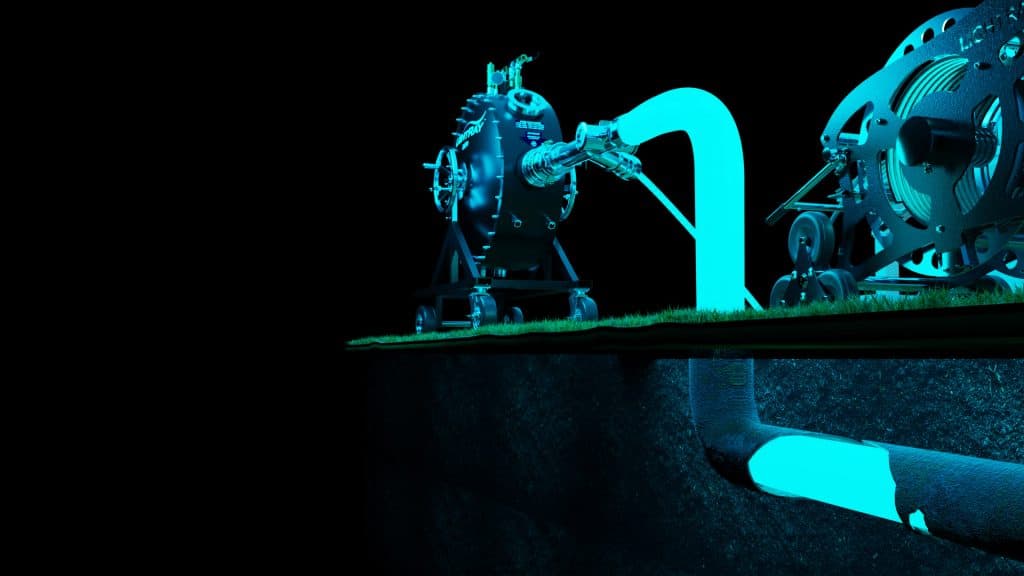

In recent years, a remarkable shift in trenchless pipe repair methodologies has emerged, with UV (ultraviolet) cast-in-place technology gaining rapid traction. As industries evolve and prioritize efficiency, cost-effectiveness, and environmental sustainability, the LightRay brand has distinguished itself as a game-changer in the world of pipe repair. But why is UV cast-in-place technology considered superior to traditional steam cure CIPP (Cured-In-Place Pipe) methods? This article explores this question in-depth, highlighting why LightRay stands out as the brand of choice.

1. Efficiency in Repairs

Efficiency is the cornerstone of modern infrastructural repair, and UV cast-in-place technology holds a distinct advantage over its steam-cured counterpart. The LightRay 2-Inch Spot Repair System, for instance, boasts rapid casting times, often completed in under 10 minutes. Compared to steam cure CIPP methods, which may require several hours, UV curing drastically reduces project completion times. This rapid turnaround is a boon not just for contractors but also for homeowners and municipal bodies eager to minimize disruptions.

2. Cost Reduction and Economic Benefits

Adopting the LightRay system presents potential cost savings when contrasted with steam cure methods. The quick curing times translate to lower labor costs. Additionally, with the simplified equipment and operations of the UV system, there are fewer overhead expenses. Thus, by integrating LightRay’s UV technology, contractors can potentially offer more competitive rates, giving them an edge in the marketplace.

3. Superior Flexibility and Adaptability

One of the standout features of the LightRay 2-Inch Spot Repair System is the unparalleled flexibility of its packer. It effortlessly navigates through bends and p-traps in plumbing systems, something steam-cured systems often grapple with. This adaptability ensures comprehensive and consistent curing even in complex pipe layouts.

4. Enhanced Durability and Longevity

The materials employed in the UV cast-in-place method, especially those by LightRay, are of premium quality. They ensure lasting durability once set. The consistent and even curing that UV light offers means that the resulting liner is robust, uniform, and less prone to weak spots or inconsistencies compared to steam-cured liners.

5. Environmentally Conscious Solutions

LightRay’s commitment to ecological sustainability is evident in its UV cast-in-place products. Their non-VOC resin ensures minimal environmental impact, especially when compared to some steam-cured methods that might use chemicals with higher volatility. By using UV technology, there’s a significant reduction in the carbon footprint of pipe repair operations.

6. Streamlined Operations and User-Friendliness

LightRay’s UV system omits the need for complex parts or computer-regulated movement. This simplicity translates to fewer operational hitches and a more user-friendly experience. The LightRay 2” control box, power pack, and pneumatic accessories pack further enhance this streamlined operation in the field.

7. Reduced Risk and Increased Control

Temperature plays a pivotal role in the curing process. Steam cure methods can be particularly sensitive to external temperature fluctuations, leading to premature or prolonged curing times. In contrast, UV cast-in-place technology, like that of LightRay, remains largely impervious to such temperature variations, granting operators enhanced control over the curing process and ensuring a consistent outcome.

8. Unmatched Support, Warranty, and Training

Choosing LightRay is not just about adopting advanced technology; it’s about investing in a partnership. All our 2″ systems come with a 1-year limited warranty and training. This ensures that contractors can utilize the technology optimally, and if issues arise, they’re backed by robust support.

9. Proudly Made in the USA

Emphasizing local craftsmanship and unparalleled quality, LightRay’s UV systems are designed, built, and supported in the USA. This not only assures high-quality standards but also promotes local industries.

While steam cure CIPP methods have served the industry for years, UV cast-in-place technology represents the next frontier in trenchless pipe repair. With its myriad of advantages, from rapid curing times to environmental benefits, it’s no wonder more contractors are gravitating towards this innovative approach. And at the forefront of this shift is LightRay, offering state-of-the-art solutions tailored for modern challenges. As the industry evolves, it’s clear that UV cast-in-place technology, especially from trusted brands like LightRay, is set to lead the way.