Applied-In-Place-Pipe-Repair

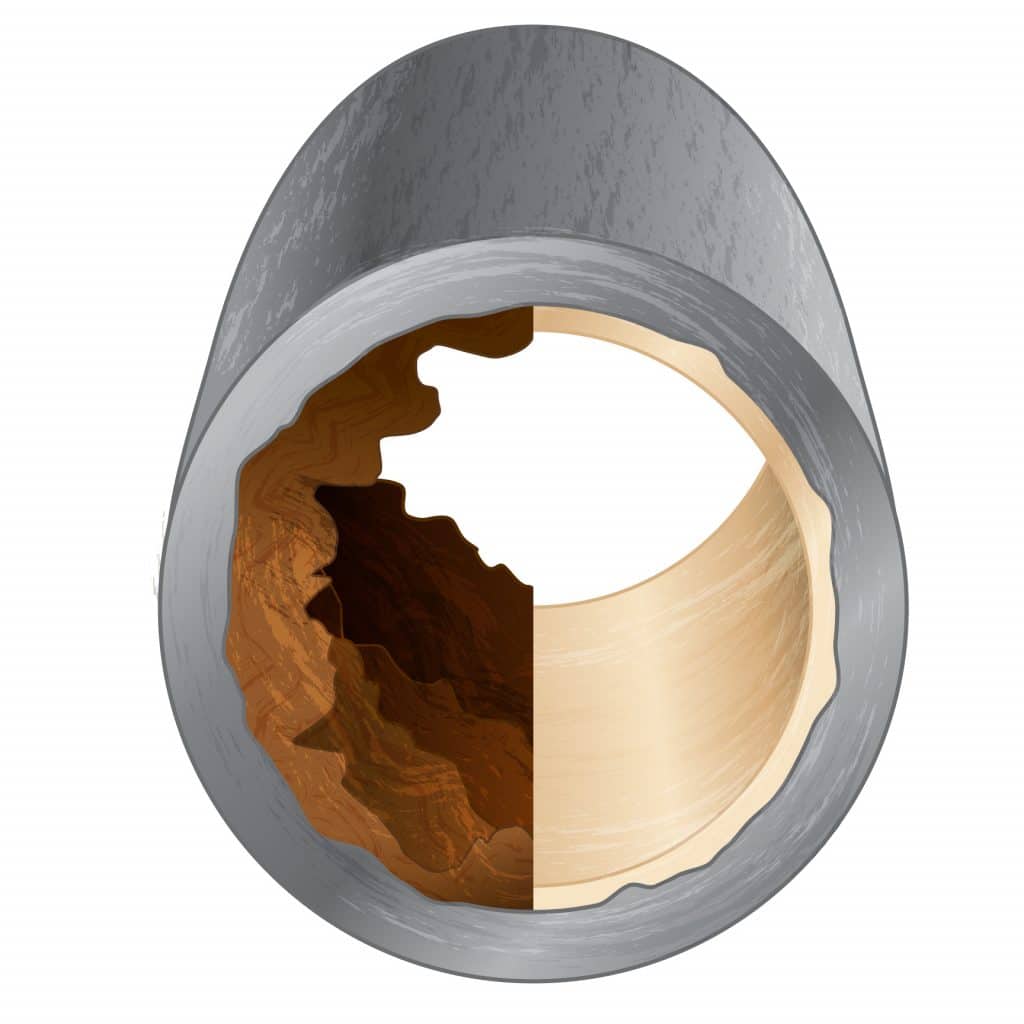

The Quik-Coating System process uses a different resin system that complies with the Uniform Plumbing Code and the International Plumbing Code standards. These standards outline a method of applying the resin system over the surface of the host pipe without any fabric. This system is referred to as the Applied In Place Pipe Rehabilitation (AIPPR) process and works in conjunction with the host pipe and not as a replacement for the host pipe by rebuilding the pipe creating a hybrid pipe that relies on filling in cracks and voids with a resin material that hardens very quickly. When completed the hybrid pipe has been reconstructed to operate under gravity sewer conditions and pass a gravity sewer pressure test.

CIPP vs. AIPPR

Here’s where AIPPR excels in rehabilitating DWV pipe with branch lines. The coating uses the remaining value in the old pipe to form a water-tight hybrid pipe. If the host pipe is found to be fully deteriorated and not capable of being rebuilt to a viable hybrid pipe, you can insert your CIPP liner to provide a stand-alone replacement pipe using your gap method or another method where your reinstate the branch lines with a cutting device to open the branch where the liner covered it. The Quik-Coating process can then be employed to seal the liner to the host pipe at each branch line tie-in by applying the coating material to the pipe covering both the exposed host pipe and the new liner. In the event the pipe is determined to be rebuildable you could use the coating process as a fix by itself. In summary, these are two completely different processes and should not be confused with each other. They conform to different standards and meet different testing processes.