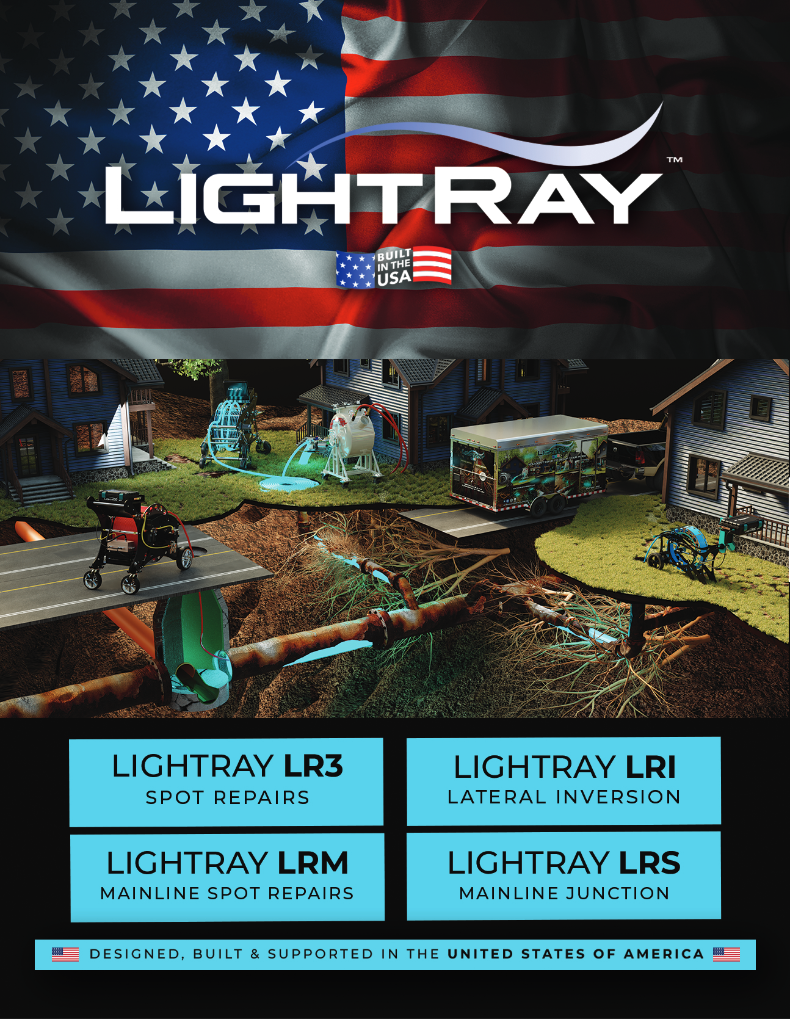

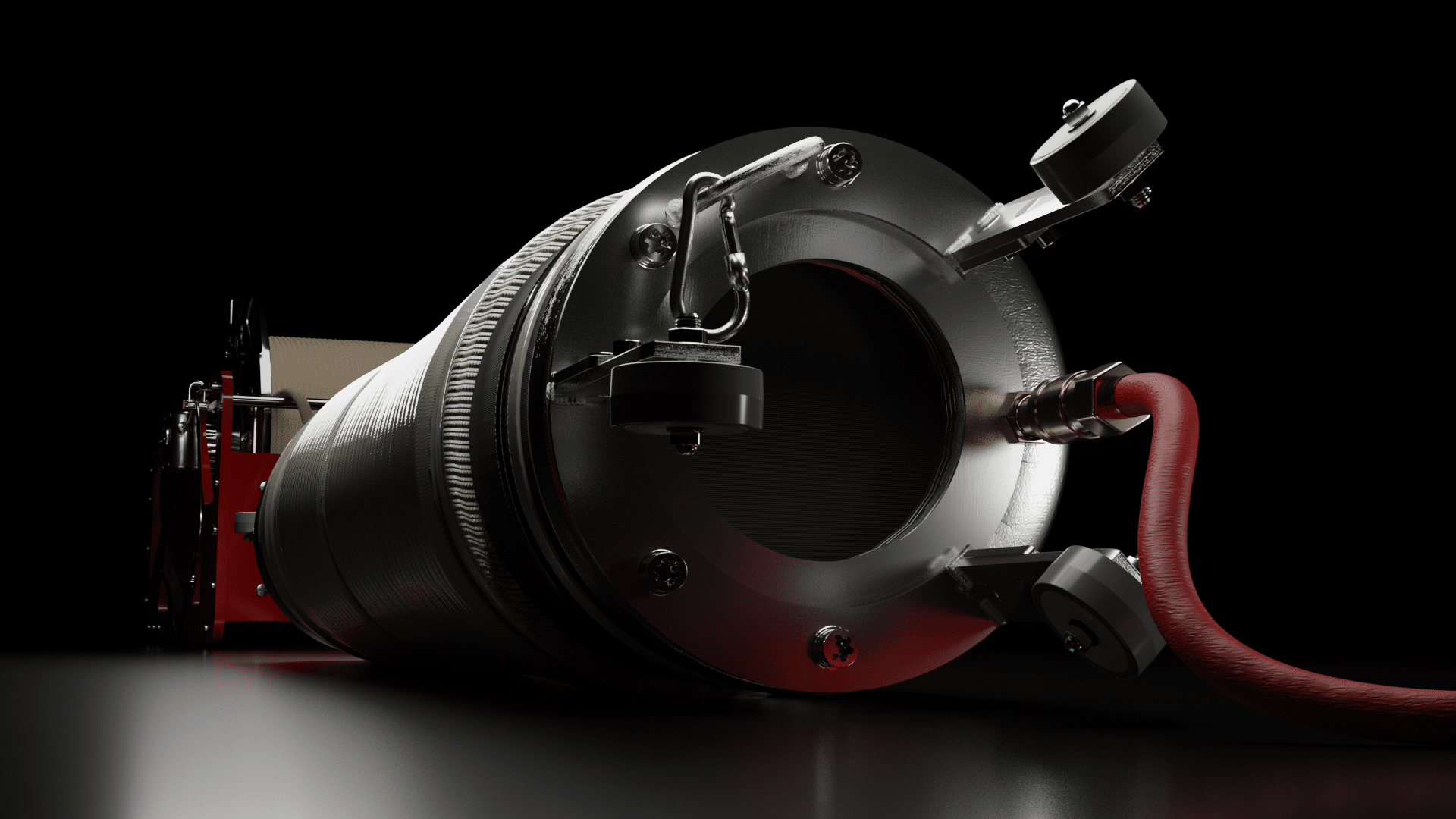

large diameter spot repair system

sectional point repair

It Is No Longer Necessary To Reline A Pipe From Manhole-To-Manhole In Order To Address One Section Of Pipe.

Perma-Liner™ Sectional Point Repair Cured-In-Place-Pipe (CIPP) Rehabilitation System. The Perma-Liner™ Sectional Lining System is designed for 6” – 48” Diameter Pipelines. The materials are pulled into place through existing manholes and are ambient cured in 3 hours or heat cured in as little as 1 ½ hours. PLI Sectional Point Repair Materials can be installed safely, fast, and efficient. Installations average 1-5 installations per day. The Perma-Liner™ Sectional Point Repairs can be installed to repair 2FT–10FT areas on average, but can accommodate lengths up to 30FT. The Sectional Point Repair materials are sold in kit form to eliminate waste, measuring and bulk storage. Installation equipment is compact and user friendly.

sectional main line spot repair system rehabilitates pipes from

6" - 48"

in diameter

repairs up to:

2-10ft

THIS ZERODIG™ TRENCHLESS SEWER REPAIR PROCESS REHABILITATES the damaged sections of main line pipe.

sectional main line point repair system is proudly made & supported in the united states of america

main line sewer repair is a breeze with the sectional point repair system

Perma-Liner™ Sectional Point Repair Cured-In-Place-Pipe (CIPP) Rehabilitation System. The Perma-Liner™ Sectional Lining System is designed for 6” – 48” Diameter Pipelines. The materials are pulled into place through existing manholes and are ambient cured in 3 hours or heat cured in as little as 1 ½ hours. PLI Sectional Point Repair Materials can be installed safely, fast, and efficient. Installations average 1-5 installations per day. The Perma-Liner™ Sectional Point Repairs can be installed to repair 2FT–10FT areas on average but can accommodate lengths up to 30FT. The Sectional Point Repair materials are sold in kit form to eliminate waste, measuring and bulk storage. Installation equipment is compact and user-friendly.

the sectional main line point repair kit benefits

- No excavation – eliminates disruptive digging and restoration

- Total time of repair is only hours compared to days

- 4 to 5 repairs can be completed in one day with a three-man crew

- In most cases, no bypass pumping is needed

- Minimum design life is 50 years per ASTM F1216 specifications

- Exceeds ASTM F-1216 testing requirements for D790 and D638 Specifications

- Reduces job costs – Labor, Equipment, materials, traffic control, bypass pumping, and unforeseen liabilities

- Provides materials for diameters up to 60 inches (1500mm) in diameter and lengths up to 30 feet (9.1440.m) in length.

- Meets EPA standards

- Utilizes 100% solids epoxy / non-shrinkage

- Subjects materials to comprehensive quality assurance procedures, and sample testing.

don't dig up your property

rehabilitate your underground sewer lines

A broken or failed sewer line does not mean you have to dig it up to repair it. We manufacture all of the equipment needed to repair underground pipelines without the need for excavation. Our sewer repair pipeline rehabilitation systems can handle pipes that range from 2 inches up to 48 inches in diameter. Experience the Perma-Liner™ difference today and save your road, yard, slab and your sanity!

Did you know?

Perma-Liner™ Sectional Point Repair materials consist of layered nonwoven flexible needled felt tube with an inner PU/PVC impermeable coating and an additional layer of reinforced chopped fiberglass and felt. The tubular material is capable of carrying a thermosetting resin, withstanding installation pressures and curing temperatures. The material is designed to stretch in order to fit irregular pipe sections.