LIGHTRAY LRM

MAINLINE SPOT REPAIR

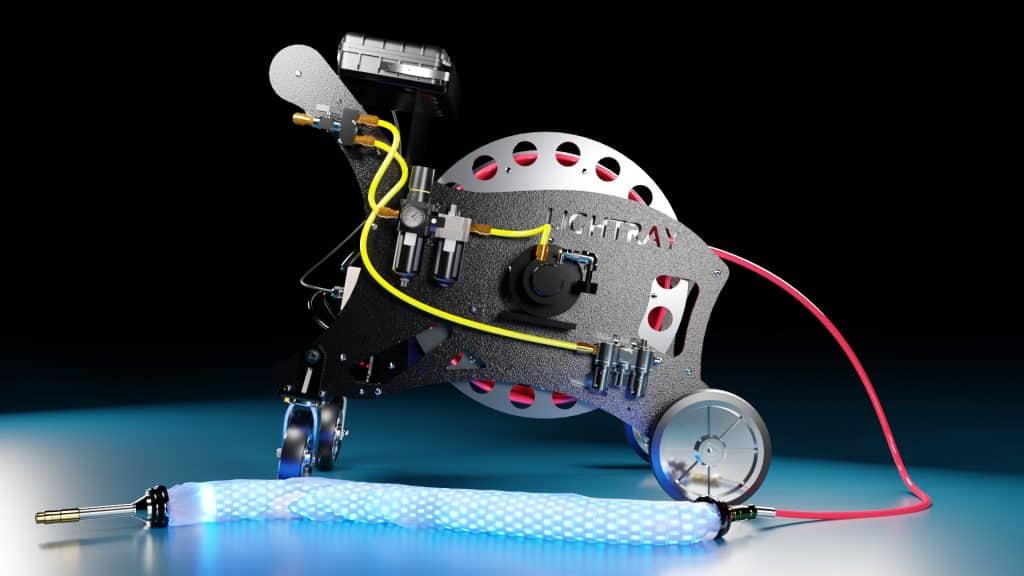

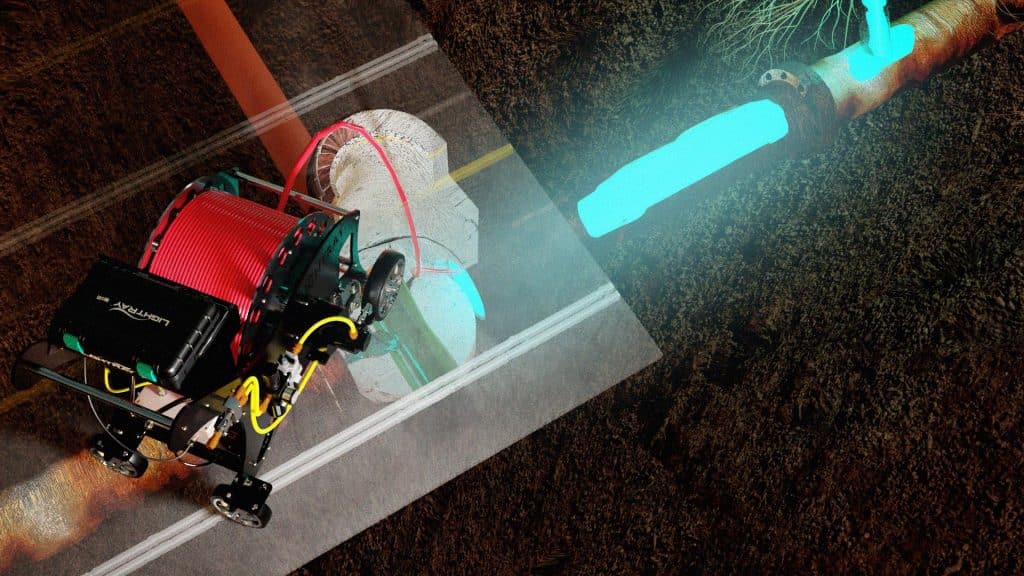

The LightRay® LRM system—an innovative solution designed specifically for UV-cured CIPP spot repair of large-diameter mainline pipes. Built on the proven performance of LightRay technology, the LRM brings precision, efficiency, and flexibility to the forefront of trenchless pipeline rehabilitation and no dig sewer repair.

Engineered to navigate standard manholes with ease, the LightRay LRM UV mainline CIPP spot repair system provides a powerful and controlled repair process without the excess heat or risks associated with traditional thermal systems. The LRM utilizes a proprietary packer and is capable of performing mainline CIPP spot repairs repairs up to 9 feet in length.

mainline cipp uv spot repairs

The LRM was designed with one goal in mind—make mainline spot repair smarter, faster, and safer. LightRay’s cold UV-cure technology, contractors and municipalities gain peace of mind knowing they can control the entire casting process, reduce variability in the field, and complete repairs in as little as 15 minutes.

mainline spot repairs

Perfect Cast in minutes

LightRay LRM System: Your Go-To for Mainline UV Spot Repair

The LightRay LRM UV Mainline CIPP Spot Repair System is your ultimate solution for mainline CIPP UV spot repair, offering the benefits of traditional spot repair systems combined with advanced LightRay technology. Here’s what makes the LRM stand out:

Compatible with 8- to 12-inch pipe diameters

Engineered for standard mainline sewer pipe sizes, ideal for municipal and utility infrastructure rehabilitation.

250-Foot Reel enables up to 500 feet of total reach

Designed for long-run UV CIPP lining between manholes, reducing setup time and maximizing trenchless repair productivity.

easily fits through standard manholes

The lightweight and compact system design ensures fast deployment for confined space access.

cures in place in as little as 15-minutes

The cold-cure UV system delivers rapid, reliable liner hardening to minimize downtime and return systems to service quickly.

No complex electronics or mechanical programming

Simplified, durable components allow intuitive operation without the risk of failure from computer-regulated parts.

Benefits of LightRay Technology

LightRay technology alleviates the stress associated with lining by offering rapid deployment capabilities:

- No Hazardous Materials: No need to carry hazardous materials in your truck or trailer.

- Ready-to-Install Liners: LightRay liners arrive ready to install, eliminating the need for on-site measuring and mixing.

- No Refrigeration Required: This reduces the variability from mixing resin and preparing liners in the field, and removes the need for extra equipment.

All LightRay technology features flexible fiberglass liners coupled with a non-thermal UV casting resin that activates only when exposed to the specific light wavelength of the LightRay packer