HOW DO UV CURING AND UV CIPP WORK?

To begin the UV curing process for CIPP, installers create two entry points on both ends of the failing pipe. These access points are not created in most cases but rather a cleanout or manhold is used. A glass-reinforced polyester (GRP) liner, impregnated with a special UV resin, is inserted into the sewer or drain pipe. Installers can also push the liner in place for applications without two access points. Once the liner is pushed or pulled into place, a bladder is inflated with air. UV lights are then activated to cure the resin, effectively creating a new pipe via UV curing with high-strength and high-durability characteristics.

THE MAIN ADVANTAGES OF UV CIPP FOR TRENCHLESS TECHNOLOGY

When considering whether UV trenchless technology may be the right solution for your next pipe rehabilitation project, contractors and engineers should fully understand the benefits that can be realized. These include:

MINIMAL PROPERTY DISRUPTION

Compared to traditional sewer pipe excavation methods, pipe relining via trenchless technology minimizes ground disturbances to property. Homeowners especially are never pleased to see their hard-earned investments or landscaping unearthed, even for a short time. Besides the unsightly damage and inconvenience caused by digging, bad backfill after a pipe dig can affect the grading and drainage of property and lead to structural issues down the line. Also, the exposal or cutting of tree roots during trenching can cause trees to die.

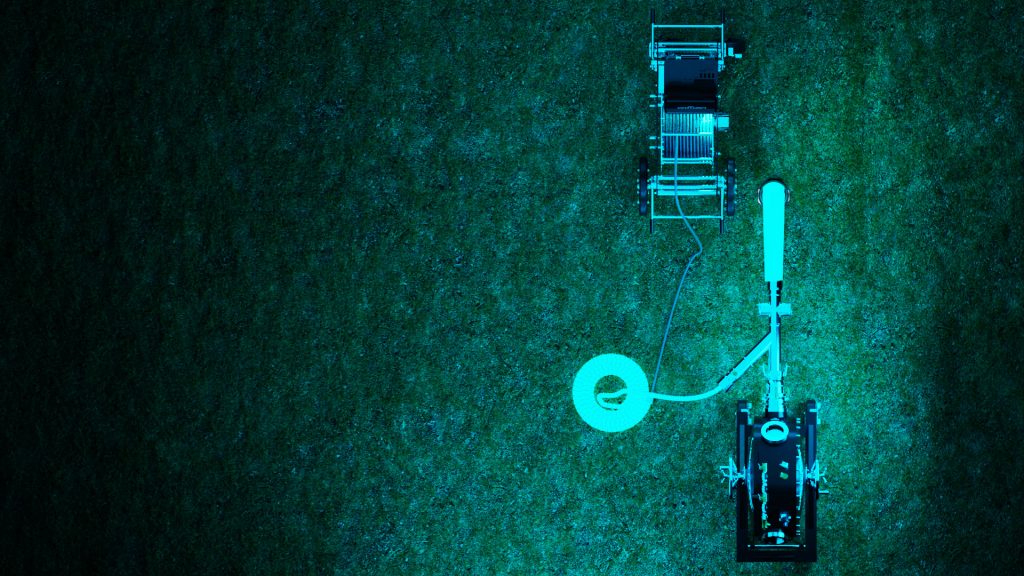

COMPACT SITE FOOTPRINT

The trenchless sewer lining equipment involved in UV CIPP projects is portable and light-weight, making trenchless technology an optimal solution for tight, hard-to-reach or sensitive areas like backyards and congested urban areas. One to two people can quickly transport the UV curing supplies, including a UV light train, liner and telescoping boom, without heavy trucks.

GREATER EFFICIENCY & FASTER CURE TIMES

With UV trenchless technology, the entire CIPP rehabilitation process goes much faster. The ultraviolet light used in UV CIPP systems cures the circumferential GRP lining in minutes. Instead of waiting hours or days for traditional curing methods to set, installers can wrap up UV curing jobs within shorter planned schedules. No major digging means less coordination, less prep and less cleanup.

CONCLUSIVELY STRONGER AND MORE DURABLE

By combining advanced fiberglass materials with modern UV curing technology, the UV CIPP lining process creates a stronger, longer-lasting pipe than traditional curing methods can achieve. UV CIPP technology has been proven in thousands of installations across North America. UV cured pipe liners are designed to withstand harsh underground conditions throughout their expected 50-year lifespan.

NO DAMAGE TO EXISTING PIPES

UV curing does not require heat and trenchless technology involves little digging, so the risk of damaging existing host pipes or surrounding pipes is greatly reduced.

IMPROVED WORKER SAFETY

Trench and excavation accidents are among the most dangerous and devastating types of worksite accidents. Serious injuries can occur from falls, cave-ins, electrocutions, explosions and heavy-machinery mishaps. This modern approach significantly reduces hazards, protecting your crew members from harm and you from personal injury lawsuits.

INCREASED FLEXIBILITY

The UV curing process is a flexible one that works for lateral and vertical pipes. Your crew can quickly go from one job site to the next with trenchless equipment that’s designed for efficiency and ease of use. The latest UV curing technologies can accommodate pipes up to 6 inches in diameter and 100 feet in length.

IMPROVED FLOW CAPACITY

While CIPP relining reduces the original pipe’s inside diameter (ID), UV cured pipe liners will often increase flow capacity. This occurs because the new liner surface is much smoother than the original pipe, resembling the surface of polyvinyl chloride (PVC) pipe. The liner thickness is also relatively thin, so the ID reduction is not very significant.

ENVIRONMENTALLY FRIENDLY

Traditional water and steam CIPP installations use a lining tube made from a styrene-based thermosetting resin that has been shown to contaminate ground sites and sewer systems due to poor installation practices, uncured resin that escaped, or some degree of permeability in the lining material. Since UV CIPP lining is made from GRP (fiberglass) and cured by ultraviolet light rather than water or steam, these inherent risks and general water disposal contamination problems are eliminated. UV CIPP’s faster cure rates also result in less energy consumption spent on bypass pumping.

READY TO MAKE THE LEAP TO UV CURING AND TRENCHLESS TECHNOLOGY?

As trenchless technology continues to evolve and create new opportunities for sewer and pipe lining repair, more opportunities will arise for contractors to set themselves apart in the project bidding stage. With UV curing and CIPP products from brands like LightRay, contractors can use state-of-the-art technology to give their customers the best. Let our team of experts at Waterline Renewal Technologies support you with top-of-the-line equipment, training and expertise that simplifies your work and increases your revenue. Contact us at (847) 994-4705 or info@waterlinerenewal.com to get the future of your business moving at the speed of UV light.